07 Jul Machinist’s Notebook: Fitting the Flywheel/Crankshaft on a Type 1 Engine

This article is about my method of fitting a flywheel to a crankshaft on a Type 1 motor. We’ll focus on the actual mating points of the two parts We must first look at the relationship between the two parts. What purpose does the crank serve to the flywheel? What purpose does the flywheel serve the crank? They meet in 3 basic forms:

This article is about my method of fitting a flywheel to a crankshaft on a Type 1 motor. We’ll focus on the actual mating points of the two parts We must first look at the relationship between the two parts. What purpose does the crank serve to the flywheel? What purpose does the flywheel serve the crank? They meet in 3 basic forms:

1. The flywheel buts up against the end of the crank.

2. The flywheel bore sits over the crank.

3. The dowels mate up with the holes in both parts.

Where they meet at the end of the crank helps determine the lateral run-out as well as keeping the pair concentric. The fit of the flywheel around the crank determines the run-out, radially. Lastly the dowels are responsible for actually driving the flywheel. Everything must be fitted very closely, as any play will exasperate itself rapidly under hard use. These considerations are important to ensure proper function

I searched to find factory specs on this, but to no avail. So here are my methods as a Machinist to achieve proper fitment.

First remove the dowels. The flywheel and the crank must be drilled together to be positive that they are in line. Check the end of the crank for trueness and perpendicularity to the axis. Once determined to be good, measure the diameters of the crank end and the flywheel bore. I like to have .0005 interference. If this is not the case you can have either (flywheel bore or crank end diameter) chromed and ground to achieve the proper press fit. By doing this, it makes certain that in actual use they remain concentric and true.

First remove the dowels. The flywheel and the crank must be drilled together to be positive that they are in line. Check the end of the crank for trueness and perpendicularity to the axis. Once determined to be good, measure the diameters of the crank end and the flywheel bore. I like to have .0005 interference. If this is not the case you can have either (flywheel bore or crank end diameter) chromed and ground to achieve the proper press fit. By doing this, it makes certain that in actual use they remain concentric and true.

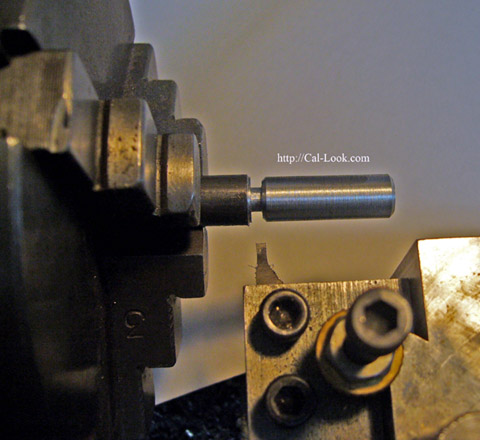

I mate the two and hold them together with a modified gland nut. I then drill and ream them for .325″ (8.25mm). This is not a readily available size, like 11/32 (.3437″, 8.73 mm). Keeping closer to the stock size of 8mm leaves more meat on the crank.

I prefer to make my own dowels from 4140 steel and harden them to about 50rc, finally grinding them to be about a .0007″ press fit in to the crank, and about .0002″ in the flywheel. This keeps them in the crank, but still holds them tight in the flywheel. Properly torque the gland nut with red Loctite and this method will produce as good a result as you can get (before converting to a flanged style arrangement).